Survey and Stake

Before any construction can begin, the home site is surveyed to establish the home's basic footprint and to ensure the home is set back the appropriate distances from the property lines. The corners of the home are marked by surveyor's stakes. Offset stakes, which are about two feet out from the surveyor's stakes, also are placed. The excavator will dig at the offset stakes, creating a slightly larger hole than the foundation actually will occupy. The extra room enables crews to work on the exterior of the foundation walls.

Excavation

The depth of the excavation is determined by a structural engineer who considers the soil, the frost line and the height of the water table (the depth in the soil at which you find water). Surface soil is removed to expose soil that is compacted enough to bear the load of the home. The excavation must be deep enough to place the top of the footing below the frost line. This prevents the concrete from cracking due to the freeze-thaw cycle of the surrounding soil. The excavation cannot be so deep that it's below the water table, however, because that can cause a chronically wet or flooded basement.

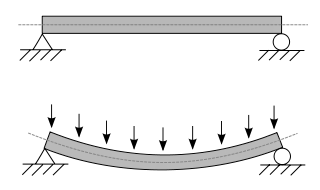

Footings

Footings are poured concrete pathways that help to spread the weight of the home from the foundation walls to the surrounding soil. Footings are wider than the foundation walls they support, and form the perimeter of the home. Sometimes, additional footings are added inside the perimeter to support load-bearing interior walls.

Sub-slab Systems

Plumbing lines are run from the street to the home's basement, by going under or over the footing. In some regions, soil gas mitigation systems are added to collect the soil gases trapped under the slab and vent them to the outside. Eventually, these systems will be covered with the poured concrete slab that is the basement floor.

Foundation Drainage Tile System

This system collects subsurface water and moves it away from the foundation. Foundation drainage tile consists of a continuous run of perforated drainage pipes embedded in gravel along the outside perimeter of the footings.

Some building codes require drainage pipes along the inside perimeter of the footings as well.

Sump

In regions where the earth is flat or the soil tends to be wet, a sump may be added to help collect subsurface water. A sump pump moves the collected water away from the home.

Walls

Foundation walls are constructed by pouring concrete between sets of form work (the total system of support assemblies for freshly poured concrete, including mold, hardware and necessary bracing.) Once the concrete gains its full strength, the form work is removed. Foundation wall thickness is determined by a structural engineer who considers the height of the wall and the load it has to bear. (Structural load is the force or combination of forces of gravity, wind, and earth that acts upon the structural system of a home). Wall thickness varies from home to home, and even within a home.

Anchor Bolts

Anchor bolts are embedded at pre-determined points along the top of the foundation walls. They'll be used during framing to secure the framing to the foundation.

Beam Pockets

Beam pockets are cast in the top of the foundation walls to receive, support, and hold beams in place.

Dampproofing and Waterproofing

A dampproofing or waterproofing seal is applied to the exterior of the foundation walls that eventually will be below-ground. This slows or stops water from traveling through the walls and into the basement.

Slab

A 3-inch to 4-inch thick concrete slab is poured between the walls. The slab helps to stabilize the base of the foundation walls, and also forms the basement floor.

Backfill

Backfill is pushed into the trenches around the exterior of the foundation walls, burying a portion or all of the walls below the surface for added stability. Ideally, backfill is soil that drains easily.